Your cart is currently empty!

Scalpel Hardtail – a weight weenie project

When you’re building a superlight bike, it’s important to not think about the cost. Shaving 1kg from a bike’s weight might only cost $1000, but taking another kilo off costs $5000…and we have 2kg to lose!

This is our summer project bike for 2022. Our objective is to build an 8kg bike that will be used for some adventure rides which include uphill hike-a-bike on bushwalking tracks in the Watagans and the Corrabare.

The bike arrived in the shop in late September, and after unpacking and assembling it, we weighed it without pedals: 10.4kg ‘dry’. The bike seems light, and for an XL frame that weighs in at 1230g we think that taking 2kg off it should be reasonably easy. Many of the easily changeable parts are just a little bit heavy and the cumulative savings on all these individual parts will be substantial.

We photographed the bike on a sunny day then immediately stripped it, sending parts to different places for upgrades. The build should be completed in November ready for some early morning adventures over the summer.

For the past few months we’ve been busy gathering parts for the build. In no particular order, here’s the details.

Handlebars and Controls

As a trail bike, the Scalpels come with a flat bar. The base models use a #2 Alloy bar, white the high-spec bikes get the #1 carbon version. Our project bike will need to be tall though, so we’ll swap out the OEM bar for a light-but-strong Renthal Carbon Fatbar with a 30mm rise. This will save about 150g without any loss in strength, plus the compliance of a flexible carbon bar.

Grips will be our favourite ESI Extra Chunky XL. These longer silicone grips are great for multiple riding positions, with maximum grip in all weather conditions.

Frame and Forks

Cannondale’s Scalpel HT is a new frame for MY22. Full carbon with dropped seatstays and flex zone chainstays, in size XL it weighs just 2kg. The seatpost is carbon 27.2, Cannondale did a great job with this new Hollowgram post, it’s only 185g.

The frame will get a custom paint job in our shop colours, with custom graphics by Sign Style.

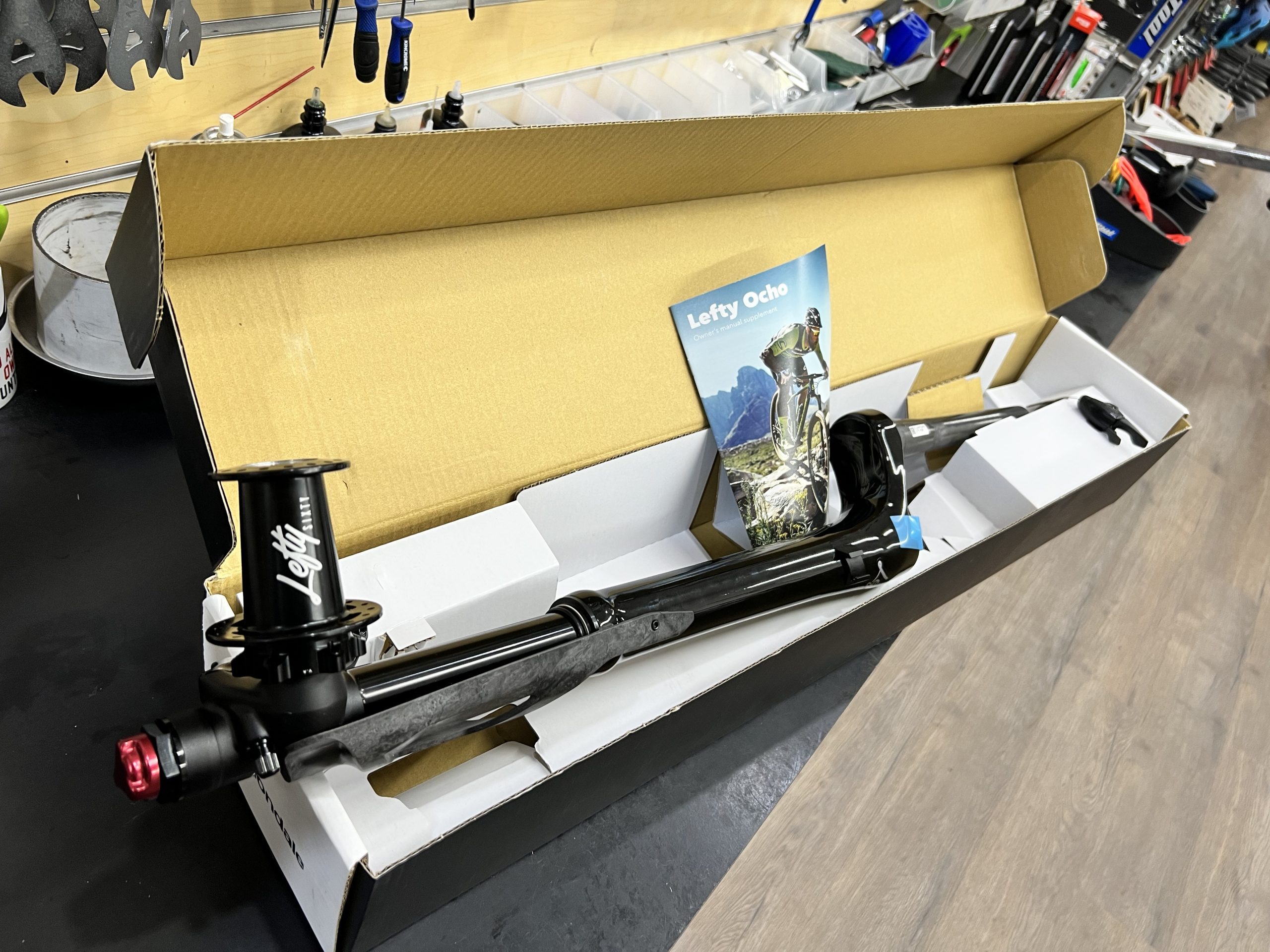

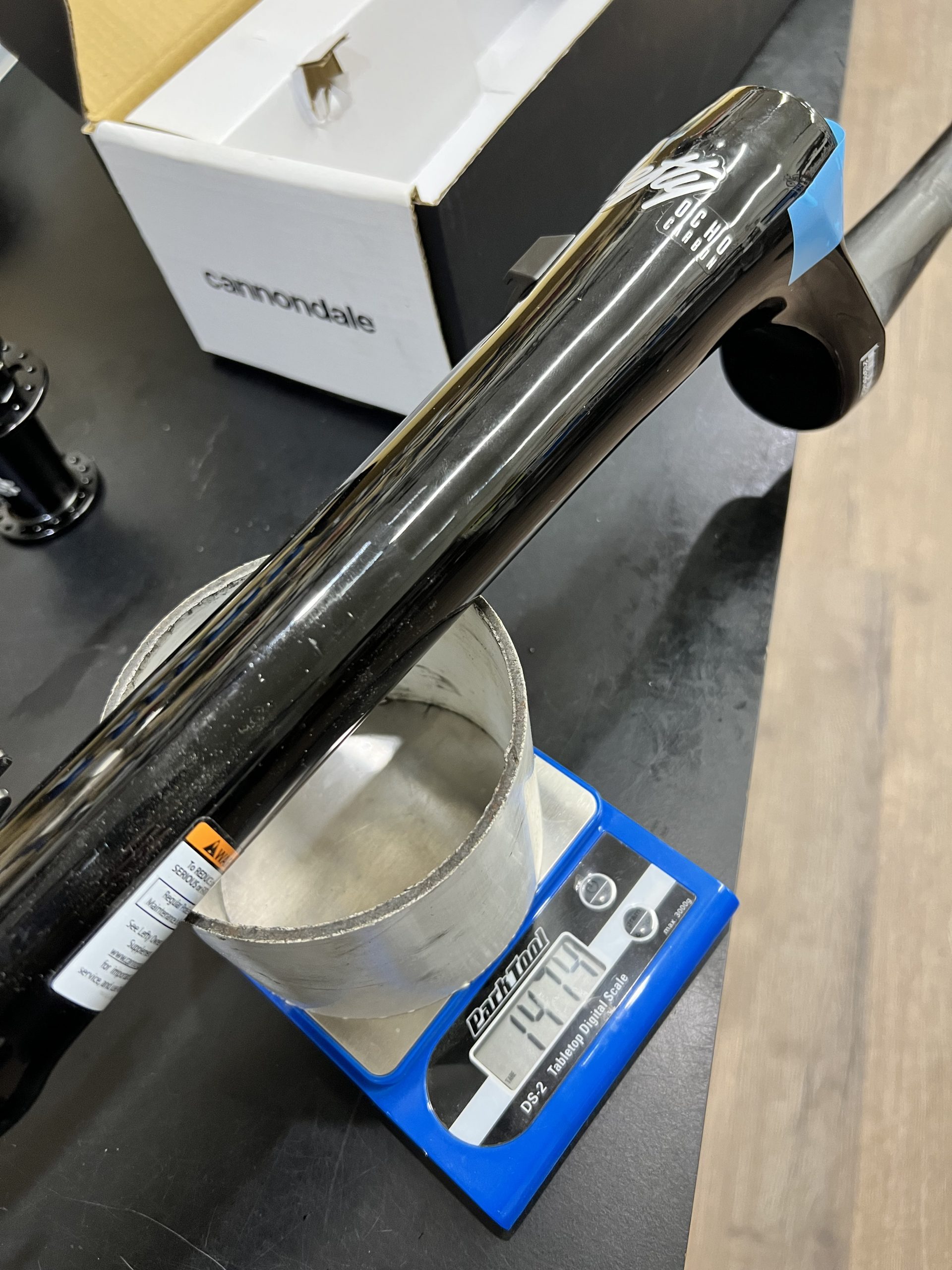

The fork we’ll use on this bike is a Cannondale Lefty Ocho Carbon with 120mm of travel. The production bike came with a RockShox SID fork which performs well, but there’s significant weight savings in the Lefty fork plus huge leaps forward in suspension performance. This fork is the XC market leader, and weighs only 1470g.

Wheels and Tyres

Reducing wheel weight is easy, but keeping strength while doing so requires carbon. Building this bike for a rider over 100kg also means 32 spokes – failure is not an option!

We started with a genuine Cannondale Lefty 60 hub, it’s the only sensible 32h option. At 130g it’s pretty good, we’ve seen some brands can get under 100g, but they’re pretty much all 28h.

The rear hub is a Hope Pro4 in 12×148 with XD freehub, this is our normal choice for rear hubs and we use them a lot on our custom wheel builds. There are lighter options out there but these are bombproof and sound great.

These Havacrak wheels are new for us and we’re loving them. Trent’s build quality is first class, he’s been building wheels for us for a while.

We expect to have these wheels available for retail sale this summer, expect about $2500 for a set with Hope hubs.

The rims we’ll use for this bike are mid-strength because of rider weight. They’re 35mm wide and will be tubeless. We’ve chosen DT Swiss double butted spokes for strength, and still the wheelset comes in at just 1.8kg.

The tyres we’re using on this bike are a first for us, and we chose them after talking to Pirelli. They had to be high quality for traction and puncture protection, but primarily they must be light. This new Scorpion XC RC Team Lite tyre has been designed together with XCO World Cup athletes for a low profile with fast cornering control. At only 610g for a 29 x 2.2 tyre, we’re super keen to try these out.

Final build on the front wheel with tyre, sealant and disc: 1634g. We’ve saved 320g over the OEM setup.

This isn’t a huge amount, but the requirement was for a super-strong wheel that wouldn’t fold under a 120kg rider, so to have a weight saving at all is a bonus.

The rear wheel is finished at 2266g, a saving of 468g. This new wheel is probably double the strength of the original wheel, we’ve gone from 28 to 32 spokes and still saved a half kilo. Worth every cent!

Drivetrain

The production Scalpel HTs are all Shimano 12sp. We have plenty of Shimano bikes and their mechanical system works really well. Retaining Shimano is a problem though, because at the top of our wishlist for this bike was electronic shifting, and Shimano’s Di2 system is overcomplicated and quite heavy.

It was never really in dispute, the new rear wheel is XD freehub and this is going to be a SRAM bike.

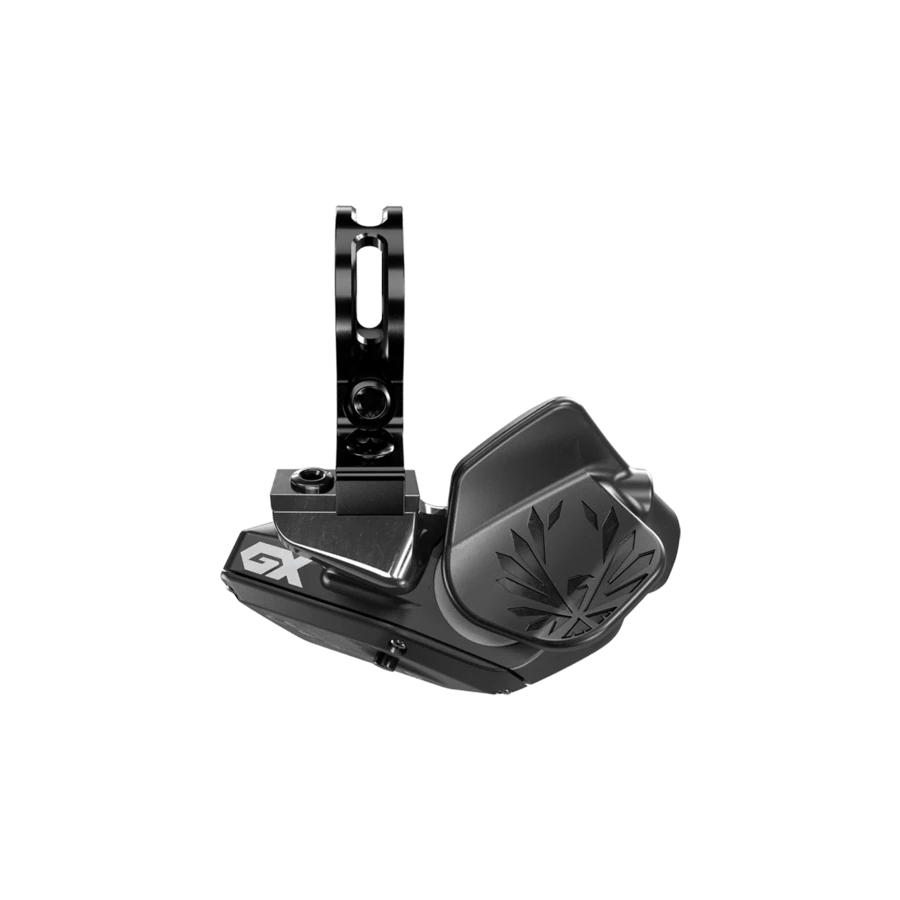

Shifting will be perfect thanks to a GX Eagle AXS wireless setup, we’ve used it before and it’s magnificent. We’ve also saved about half a kilogram in this upgrade alone which makes it great value for money.

AXS is by far the most accurate shifting system ever, SRAM have completely nailed their wireless system for performance, configuration options and tuneability.

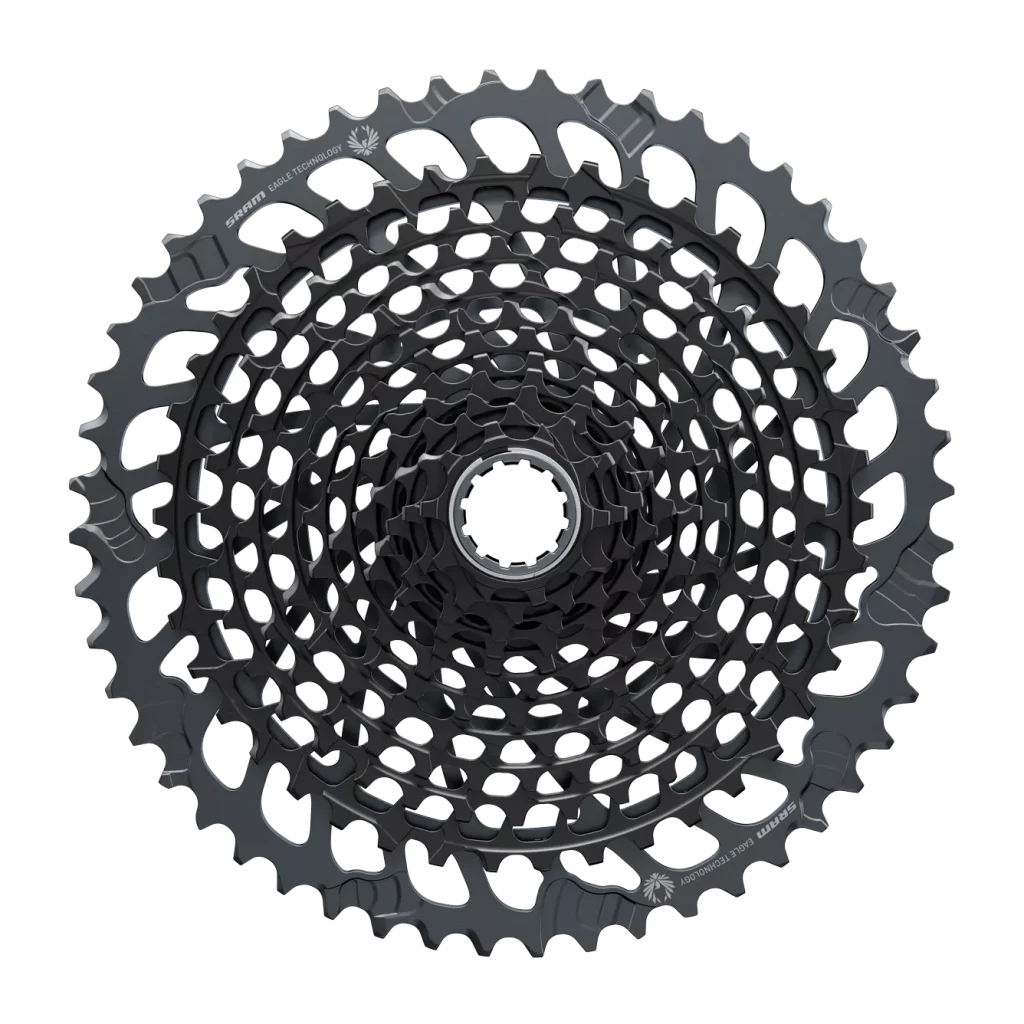

The rear cassette is XG-1295 10-52 for maximum range on the trails. Saving 50g with an XX1 optional cassette (at double the price!!) is not necessary, but we will use an XX1 chain for strength and weight.

Brakes

This bike is never going to have huge brake demands, so we’ll retain the production Shimano M6100 brakes for now. The Deore system is efficient and light, and should be fine with 160mm discs.

If they underperform we have a set of Code RSC waiting…

—

The build continues!